In India alone, around 353 million women and adolescents use sanitary pads. Given that each may use eight sanitary napkins on an average during their monthly cycle, around 12.3 billion pads are being disposed of every year, leading to an annual menstrual waste of a whopping 113,000 tonnes, estimates Toxic Links, an environmental NGO, in its report ‘Menstrual Products & Their Disposal’. Sanitary pads are typically disposed of in two ways — they are either buried in landfills, and that takes 500-800 years for them to decompose each — or are burned in incinerators that release toxic fumes like dioxins, phuron, and other carcinogenic compounds into the atmosphere.

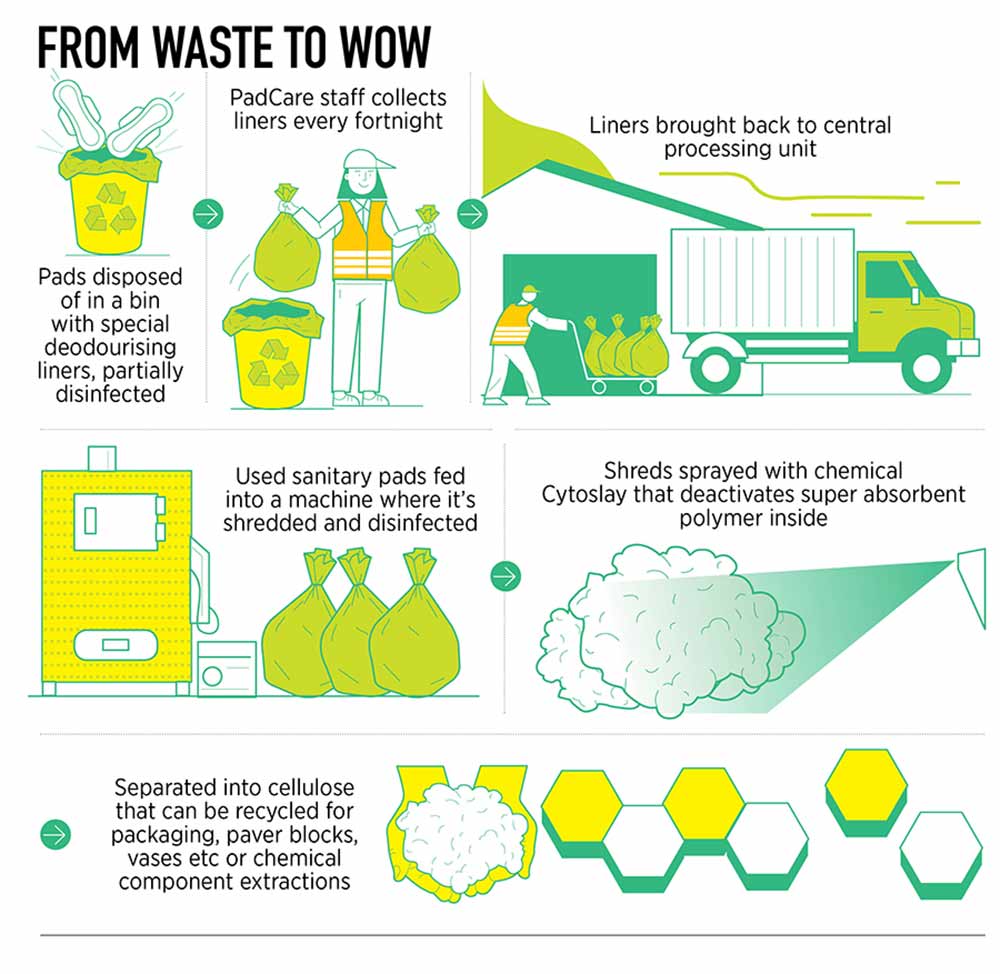

In 2018, a year after graduating from college, Ajinkya Dhariya, a mechanical engineer set up the company, PadCare Labs, and designed a machine that could disinfect and shred used sanitary napkins, pass it through a solution to deactivate the super-absorbent polymer and separate the components into recyclable cellulose that could be used in the packaging industry, or to manufacture vases, paver blocks, what have you.

The company went commercial in March 2020 and has on boarded 16 corporate clients in Mumbai and Pune, including the likes of P&G, JSW and Raymond. Almost 550 units of the bins, which are fitted with special liners developed in-house, which can deodorise and partially disinfect the pads for 30 days, have been installed in the offices of his clients. As of now, he houses a central processing unit at his workplace in Pune’s Pashan, along the Mumbai-Pune highway, but is manufacturing four more for locations across Mumbai, Bengaluru, Hyderabad and Gurugram.

Dhariya explored a number of sectors during his college—energy, sustainability—but once he ran into the problems of menstrual hygiene management, he was hooked. “This was a new space and we had no data. We had to finetune our machine by conducting more than a thousand trials, some at the washrooms at the Venture Center itself,” says Dhariya in an interview with Forbes India. The initial idea was to mount the machines on the wall, like hand-dryers, and have an integrated processing unit in the washroom itself. “But most cubicles in an Indian washroom don’t have a plug point, or additional water connection for the machine to function. Besides, most women aren’t so much interested in how the pads are processed; they just want some privacy and a hygienic disposal,” adds Dhariya. “That’s how we came up with the idea of splitting the bin from the processing unit.”

Along with the bins, PadCare has also developed sanitary napkin vending machines that operate on digital pay. For this, the company has tied up with a number of eco-friendly pad manufacturers. “When a woman disposes a sanitary napkin, chances are she will need another,” says Dhariya. “This closes the circular economy loop at a local level.”

PadCare’s modernistic waste management system aims to reform the job of waste-pickers as well by making it truly dignified and safe.